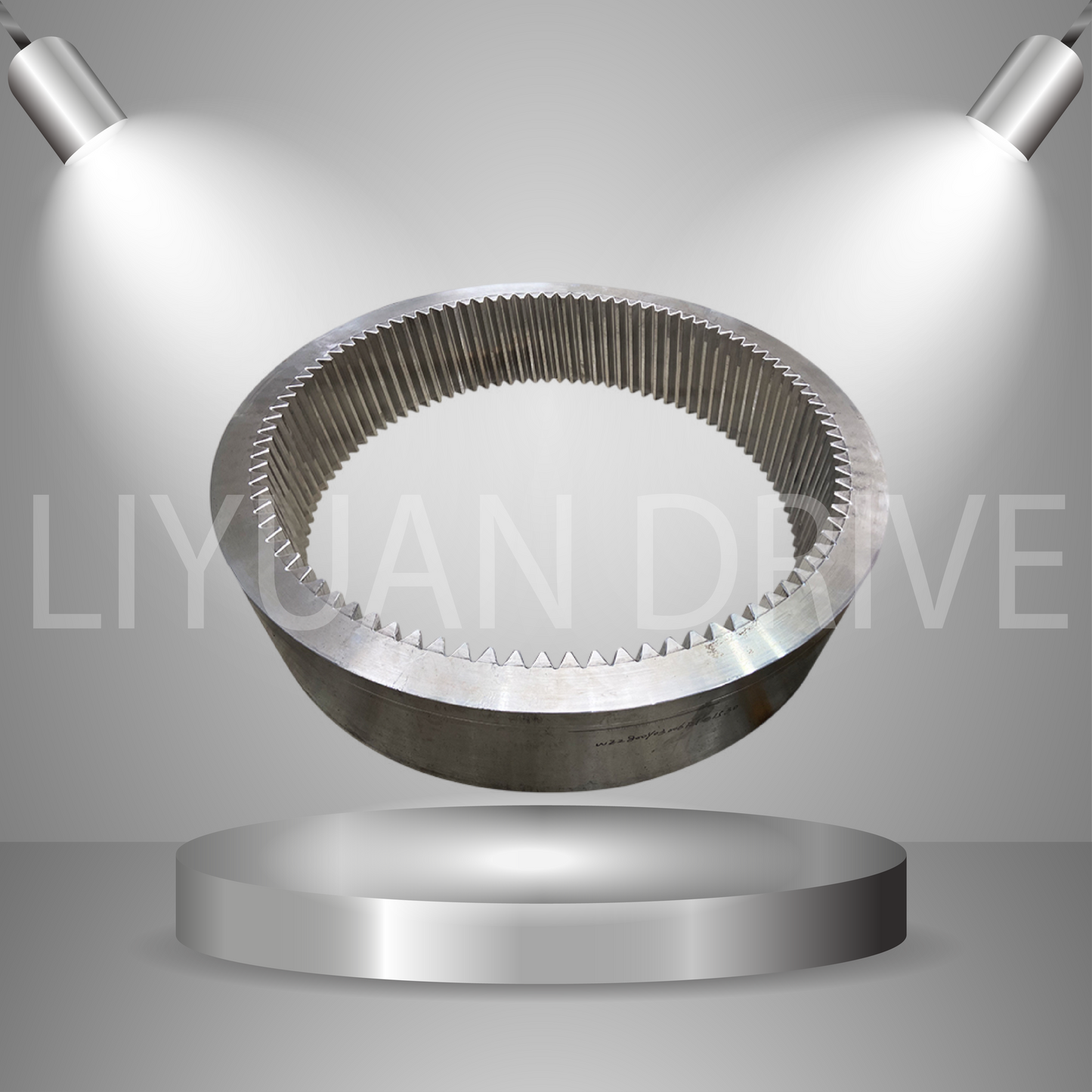

PRODUCTS APPLICATION

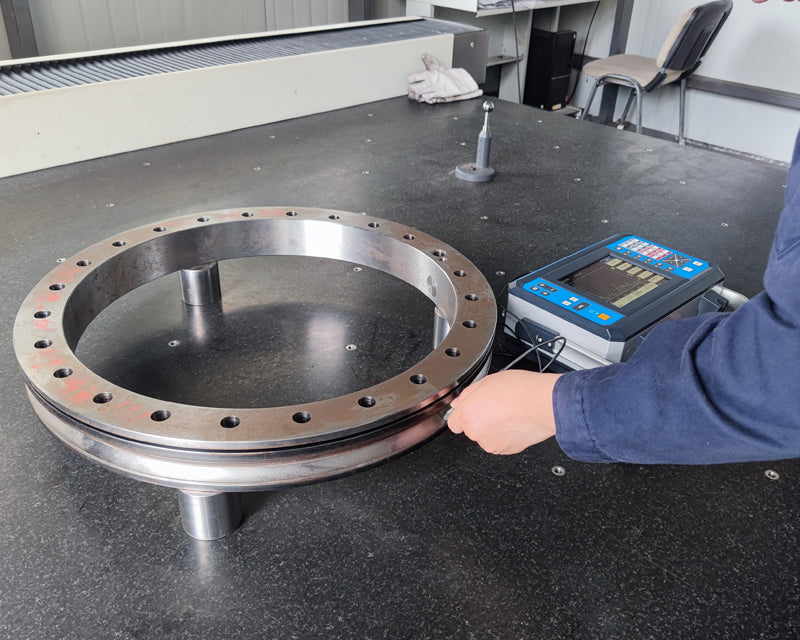

Examination Equipment Glance

Metallographic Microscope

A Metallographic Microscope examines metal microstructures at high magnification, revealing details invisible to the naked eye.

Coordinate Measuring Machine

A Coordinate Measuring Machine precisely measures object dimensions using a probe system. Essential for quality control in manufacturing.

Direct Reading Spectrometer

A Direct Reading Spectrometer instantly analyzes material composition by measuring emitted light wavelengths. Essential for rapid quality control in metallurgy.

Hardened Layer Depth Detector

Hardened Layer Depth Detector measures hardened surface thickness on metals. Essential for quality control in heat treatment processes.

Magnetic Particle Flaw Detector

Magnetic Particle Flaw Detector reveals surface and near-surface defects in ferromagnetic materials. Essential for non-destructive testing in manufacturing and maintenance.

Production Equipment Glance

LIYUAN DRIVE is equipped with advanced manufacturing equipment and a comprehensive production line, ensuring high precision and reliability of our products. Our production facility features 1.8m CNC gear milling machine, 3m CNC drilling machine, precision CNC vertical lathe, and CNC gear grinding machine, enabling precise machining of various complex components. Additionally, our heat treatment furnace guarantees optimal hardness and durability of materials, while the 800-ton hydraulic press provides powerful support for large component forming. This advanced equipment allows us to meet customer demands for high-quality drive products while ensuring production efficiency and product consistency.

Precision Processing Technology

We excel in advanced precision processing technology, ensuring unparalleled quality and innovation in every detail.

“Customer service shouldn’t just be a department; it should be the entire company.”